The similarities and differences in the chemistry of carrageenan results in a functionality gradient from thickening only (Lambda type) through elastic gel formaion (Iota type) ending with brittle, firm gels (Kappa type). The applications for this group of hydrocolloids depends not only on the type of Carrageenan but also the presence of other components in the formulation. The gelling functionality of all Carrageenans is influenced by the presence of proteins and calcium ions. Proteins can either enhance or deter the gel formation, while calcium ions will always enhance gel strength and thickening functionality. All types are cold water dispersable. Lambda type is used in instant and cold process applications while both Kappa and Iota types require heat in processing for ideal functionality. With adjusted usage levels, both Kappa and Iota types can deliver thickening and suspension functionality and are used in beverages containing proteins (chocolate milk, alternative milk, meal replacement and sports recovery beverages) using either batch, HTST or UHT processing. At slightly higher usage levels, Carrageenan is used to enhance protein gels (cultured dairy products, processed cheese) or add gel texture (dessert gels, custards, fillings, glazes, icings) either alone or in synergistic combinations (Xanthan, Locust Bean Gum, Tara Gum, Agar). Carrageenan is available in standard grade which is organic compliant.

Carrageenan

Common Names

- Carrageenan

- Irish Moss

Functionality

- Suspension

- Gel Formation

Quality

- Refinement Grades

- Gel Strength

Applications for Carrageenan

Botanical Sources

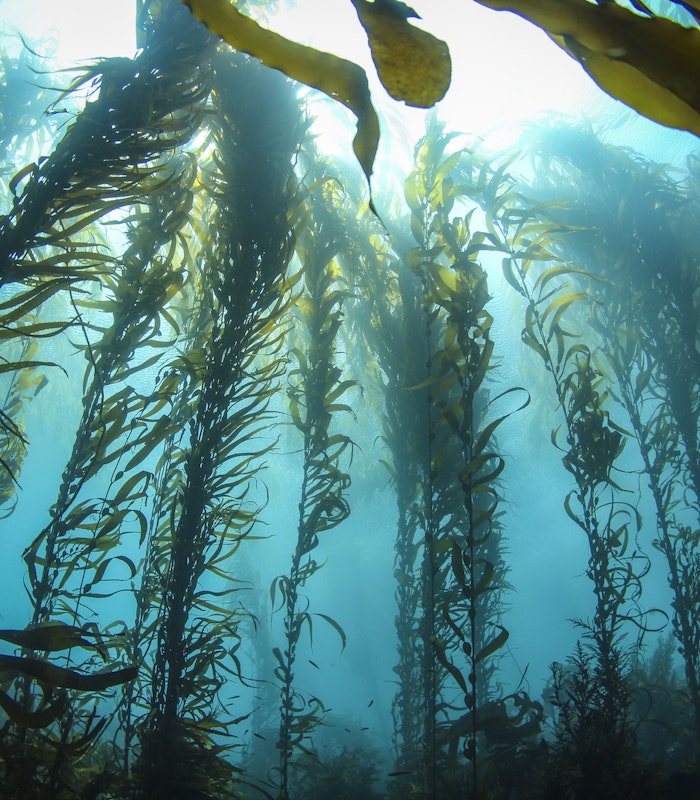

Carrageenan is a family of polymers isolated from cell wall polysaccharides from several species of red algae. These seaweeds are harvested around the world, commercial production from sites off the coasts of Chile, Mexico, Spain, Japan and the Philippines. Algal sources include: Chondrus crispus, Kappaphycus alverezii, Gigartinia spp (kappa-type), Euchema denticulatum (iota type), Gigartinia spp, Chondrus crispus (lambda type). The harvested seaweed is first cleaned and then fresh processed or dried. Processing includes alkaline extraction, concentration, sashing, filtration and drying. Differences result in two common grades of Carrageenan: fully refined or semi-refined. Grades vary in gel strength, clarity, color and odor. Fully refined grades may contain standardizing aids to decrease variability.

Polymer Chemistry

The polymer backbone of all types of Carrageenan is a liner chain of monosaccharides combining galactose and 3,6-anydrogalactose. Linked to this backbone are sulphate groups composed of a sulfur atom and 4 attached oxygen. It is the distribution and number of these attached sulphate groups that distinguishes the types of Carrageenan and has a large influence on their differences in functionality. The sulphate groups are negatively charged and also influence the three-dimensional structure of the polymers in addition to functionality. The functionality of these sulphate groups reduces gel functionality of the Carrageenans, in general. Lambda-type has the highest amount of sufate groups, iota-type is intermediate, and kappa-type is the lowest. As a results kappa type forms hard, brittle gels with highest protein reactivity, followed by more elastic gels from iota, and no gelling only thickening from lambda-type.